stainless steel mesh belt

Sintering furnace mesh belt

Sintering furnace mesh belt, also known as heat treatment metal wire mesh belt, brazing furnace mesh belt, oven mesh belt, metal conveyor belt, stainless steel mesh belt, metal mesh belt, tunnel furnace mesh belt, high-temperature mesh belt, metal conveyor belt, etc.

Materials: galvanized iron wire, low-carbon steel wire, stainless steel wire, stainless steel wire, alloy wire, etc.

Parameters: Mesh belt width 5cm-800cm, operating temperature -40-1300 ℃, edge form bending, heading, welding.

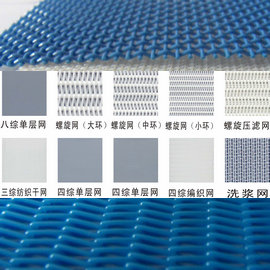

(1) Types of metal mesh belts

1. Ordinary mesh belt: It combines various advantages of metal wire woven mesh belt. Due to its deep bending string, the position of each spiral coil is correctly positioned, thus minimizing the deformation and extension of the mesh belt.

2. Straight through strip mesh belt: It is composed of alternating left and right straight string connections. This series of mesh belts have dense mesh holes and uniform spacing between mesh holes, which can make the mesh belt walk smoothly. This series of mesh belts is suitable for carrying conveyor lines with small volume and relatively heavy texture.

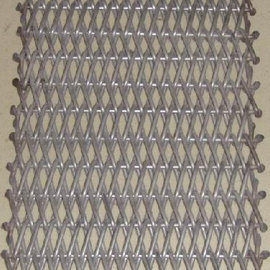

3. Flat wire mesh belt: This mesh belt is made of rolled flat wire. It is connected by a crankshaft shaped threading strip to ensure the correct positioning of each spiral coil, thus minimizing the deformation and extension of the mesh belt. Its workmanship is fine, the surface is flat, both sides are parallel, the material is excellent, and it is durable.

4. B-shaped mesh belt: also known as trapezoidal mesh belt or straight mesh belt, this mesh belt is usually a gear transmission mesh belt, which has the advantages of good breathability, uniform tension, fine workmanship, flexible rotation, good stability, high temperature resistance, pressure resistance, corrosion resistance, and long service life.

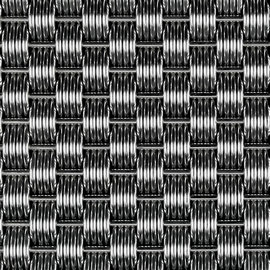

5. Composite mesh belt: also known as a human mesh, it is composed of alternating mesh strips connected by four straight strings. The precise weaving technology makes the mesh belt have the characteristics of high density, fine mesh holes, and flexible operation, which requires extremely high material and weaving technology. This mesh belt is suitable for conveying small loads on conveyor lines and can be flipped over

6. Chain type mesh belt: The conveyor mesh belt driven by the chain is generally driven by the chain to drive the small shaft and then drive the mesh belt to run. The mesh belt is made up of two strands of rolled teeth and left and right mesh bars, connected by large and small mesh bars. The large mesh bars are threaded into the small shaft, and the two ends of the small shaft are threaded into the chain hole, thereby achieving chain driven conveyor mesh belt. The chain network transmission is stable and the transmission torque is small.

7. Chain plate mesh belt: driven by stainless steel chains and produced from stainless steel plates, suitable for conveying small high-density objects. The conveying process runs smoothly, is easy to install and replace, is expensive, and has a long service life.

8. Barrier type mesh belt: This hard edge edge treatment provides an intuitive and concise conveying method. After S-shaped treatment, the baffle forms a straight groove shape. Mechanical compression should be avoided during use, and any detachment should be dealt with promptly.

9. Ball shaped mesh belt: A ball shaped spiral combination mesh composed of four spiral coils, with a sturdy structure and a large effective filtration area. It is mainly used for filtration in the chemical industry and drying in vacuum dryers. It is currently widely used in viscose fibers.

10. Plate type mesh belt: also known as reinforced mesh belt, this mesh belt string can be used in two types: straight string and curved string. The mesh belt edge can be made into a baffle, the mesh belt can be flipped as a whole, and the string can be produced and processed into a stepped edge (twisted edge), which can be determined according to the user's usage range and temperature?

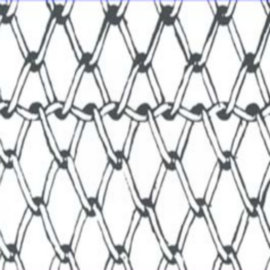

11. Diamond mesh belt: also known as hooked mesh or movable mesh

(2) The characteristics of metal mesh belts

Metal mesh belt is a friction driven mechanical device that continuously transports materials. By applying it, materials can be transported on a certain conveyor line, forming a material transportation process from the initial feeding point to the final unloading point. It can transport both fragmented materials and finished items. In addition to pure material transportation, it can also be combined with the requirements of the production process in various industrial enterprises to form a rhythmic assembly line for transportation. So metal mesh belts are widely used in various modern industrial enterprises. It is an essential and important accessory in automatic devices and modern automated assembly lines in various industries.

(3) The application industry of metal mesh belts

Common specifications of metal mesh belt: conveyor mesh chain | stainless steel mesh belt | mesh belt, automatic assembly line metal transmission mesh belt, heat treatment furnace high-temperature resistant mesh belt; Stainless steel mesh belt; Conveyor belt; Tunnel kiln mesh belt; Great Wall mesh belt; Drying mesh belt; Painting equipment mesh belt; Spraying equipment mesh belt; Cleaning machine mesh belt; Food mesh belt; Food cleaning conveyor chain plate; Stainless steel chain plate; Herringbone mesh belt; Double rotating energy-saving mesh belt; Fuel injection cooling mesh belt; B-shaped mesh belt; Baffle conveyor belt; Chain conveyor belt; Fruit and vegetable cleaning mesh belt; Quick freezing machine chain network; Single freezer chain network; Quick frozen horseshoe net chain; Special conveyor chain network for vegetable dehydration production line equipment.

The product is mainly used for automatic devices and assembly lines in various industries such as glass bottles and cans, food, lamps, metals, vessels, chemical fibers, printing and dyeing, medicine, electronics, powder metallurgy, heat treatment, wood, logistics transportation, etc; The transmission and use of various kiln systems such as natural gas, coke oven gas, and electronic infrared, as well as food machinery, glass machinery, and conveying machinery.

Main features of the product: it has special functions such as flat mesh surface, high strength and hardness, strong corrosion resistance, high tensile strength, good breathability, not easy to deform, and durability.

Troubleshooting method for the use and installation of metal mesh belts

1: If there is a deviation of the mesh belt, adjust the tension shaft at one end of the driven shaft slowly and remember to adjust it quickly to avoid scratching the edge of the mesh belt.

2: If the mesh belt shakes, the conveyor frame and the rollers inside the conveyor tunnel should be checked for rust and refusal to rotate, and adjusted one by one.

3: If the chain driven mesh belt experiences chain jumping and unstable operation, it should be checked whether the sprockets at both ends of the driving shaft are synchronized and whether the tooth ends are excessive.

Categories

News

Contact Us

Contact: Made in China metal mesh belt, stainless steel mesh belt, conveyor mesh belt, PTFE mesh belt, polyester mesh belt, metal decorative mesh - Maoqun silk mesh

Phone: 0086-13703187202

Tel: 0086-0318-7713116

E-mail: 125610838@qq.com

Add: Silk Screen Industrial Park, Anping County, Hebei Province, China