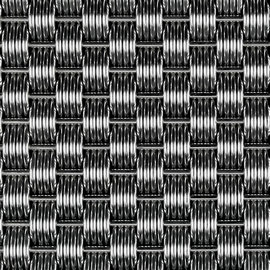

PTFE mesh belt

Iron (Special) Fluorine Grid Conveyor Belt

Iron (Teflon) mesh conveyor belt, also known as Teflon mesh belt, Teflon mesh belt, PTFE mesh belt, PTFE mesh belt, PTFE mesh belt, PTFE mesh belt, PTFE mesh belt, PTFE mesh belt, etc.

Our company has introduced advanced imported looms, using high-quality high-strength imported fiberglass and Kevlar (aramid) as substrates to weave high-strength mesh substrates, and then coating them with high-quality PTFE resin to make the PTFE mesh conveyor belt substrate.

The main characteristics of Teflon (Teflon) mesh tape:

a. Temperature resistance - from low temperature -140 ℃ to high temperature of 320 ℃, with a maximum temperature resistance of over 360 ℃.

b. Breathability - the breathability of conveyor belts, reducing heat source consumption, and improving drying efficiency

c. Corrosion resistance - unaffected by most chemicals and solvents

d. Anti adhesive - can easily remove almost all adhesives such as resins, coatings, chemicals, etc

e. Bending fatigue resistance - it has high tensile strength and bending fatigue resistance, and can be used on smaller wheels.

The application scope of Teflon mesh cloth

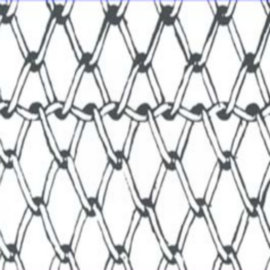

Textile printing and dyeing, printing drying guide belt, screen printing, UV drying, UV series photo curing machines, offset printing machines, pine drying machines, non-woven fabric drying machines, high-frequency drying machines, food drying machine guide belt, temperature controlled drying room, rapid drying of flux type inks, and drying of general moisture containing items. Suitable for conveying belts in the post printing drying room of flat width dryers, flat width dryers, round screen printing machines (flat screen printing machines) in the printing and dyeing industry; Drying production lines and conveyor belts for silk screen, electronics, and circuit board industries; UV curing machine conveyor belt in the printing industry; Coating machines, gluing machines, and composite conveyor belts in the packaging materials industry; Drying production line conveyor belt in the food industry; Microwave dryer conveyor belt, etc. It is an ideal replacement for traditional wire mesh conveyor belts

The main performance characteristics of Teflon mesh conveyor belt:

1. It is used between low temperature -196 ℃ and high temperature 300 ℃, with weather resistance and aging resistance. Through practical application, if left continuously for 200 days at a high temperature of 250 ℃, not only will the strength not decrease, but also the weight will not decrease; Placing at a high temperature of 350 ℃ for 120 hours only reduces weight by about 0.6%; It can maintain its original softness at ultra-low temperatures of -180 ℃.

2. Non adhesive: It is not easy to adhere to any substance. Easy to clean various oil stains, stains, or other attachments attached to its surface; Almost all adhesive substances such as paste, resin, and coating can be easily removed;

3. Resistant to chemical corrosion, capable of withstanding strong acids, alkalis, aqua regia, and various organic solvents.

4. Good dimensional stability (elongation coefficient less than 5 ‰) and high strength. Has good mechanical properties.

5. Anti bending fatigue, can be used for smaller wheel diameters.

6. Drug resistance and non toxicity. Almost resistant to all medicinal items.

7. Fire retardant and flame retardant.

8. Breathability - the breathability of conveyor belts, reducing heat source consumption, and improving drying efficiency.

Application range of Teflon mesh conveyor belt:

A: Textile, printing and dyeing: drying of printed fabrics, drying of bleached and dyed fabrics, drying of fabric shrinkage, drying of non-woven fabrics, etc., drying conveyor belts in drying rooms.

B: Screen, printing: loose drying machine, offset printing machine, UV series light curing machine, paper oil drying, ultraviolet drying, plastic product screen printing drying, etc., drying conveyor belts in drying rooms.

C: Other items: high-frequency drying, microwave drying, freezing and thawing of various foods, baking, heat shrinkage of packaged items, drying of general moisture-containing items, rapid drying of flux-type inks, etc. Drying room guide belts.

All occasions requiring hot air flow and thermal processing transmission conditions are suitable for the use of Teflon mesh conveyor belts.

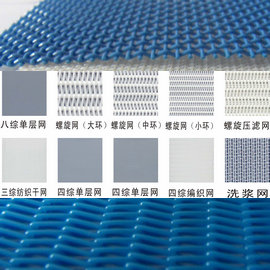

Teflon mesh conveyor belt specifications

Thickness: 0.2-1.35mm.

Width: 300-4200mm.

Mesh: 0.5-10 mm Square (4X4 mm, 1X1 mm, etc.).

Color: Light brown, dark brown, black.

In addition: "Kevlar PTFE mesh" can be processed according to customer requirements.

Main specifications of Teflon mesh conveyor belt:

Model No. Mesh size Material Thickness Weight Temperature resistance Maximum width Tensile strength

6001 1x1mm Glass fiber 0.5mm 370g/m² -70 -260℃ 4000mm 310/290N/cm

6002 2x2mm Glass fiber 0.7mm 450g/m² -70 -260℃ 4000mm 350/310N/cm

6003 4x4mm Glass fiber 1.0mm 400g/m² -70 -260℃ 4000mm 390/320N/cm

6004 4x4mm Glass fiber 1.0mm 450g/m² -70 -260℃ 4000mm 390/320N/cm

6007 4x4mm 6012 4x4mm Glass 1.0mm 550g/m² -70 -260℃ 4000mm 395/370N/cm

6013 10x10mm

Glass 1.2mm 450g/m² -70 -260℃ 4000mm 360/300N/cm 6014 10x10mm Glass

1.2mm 500g/m² -70 -260℃ 4000mm 395/370N/cm 6015 10x10mm Glass 1.2mm 550g/m²

-70 -260℃ 4000mm 360/300N/cm

6014 0.5x1mm Glass fiber 0.5mm 420g/m² -70 -260℃ 4000mm 310/290N/cm

6015 2x2.5mm Glass fiber 0.9mm 600g/m² -70 -260℃ 3000mm 390/320N/cm

Categories

News

Contact Us

Contact: Made in China metal mesh belt, stainless steel mesh belt, conveyor mesh belt, PTFE mesh belt, polyester mesh belt, metal decorative mesh - Maoqun silk mesh

Phone: 0086-13703187202

Tel: 0086-0318-7713116

E-mail: 125610838@qq.com

Add: Silk Screen Industrial Park, Anping County, Hebei Province, China